Air cooled heat exchanger is an equipment that use air as the cooling medium to cool or condense the fluid inside of its fin-tube.

An air cooled heat exchanger consists of fin tube bundles, fan, louver, framework, maintenance platform and other components required by the users.

Air cooled heat exchangers feature low maintenance cost, safe and reliable operation and long service life. Many users select air cooled heat exchangers in their project because water usage issue and water pollution issue are eliminated. So it’s mainly used in the area lack of water.

Air cooled heat exchangers are widely used in metallurgy, petrochemical industry, chemical industry, pharmaceutical industry, coal industry, electric power industry, etc.

Induced Draft Type

The fin-tube bundle is mounted below the fan and air duct. Induced draft type air cooled heat exchanger has stable heat exchange performance because the air duct can keep the fin tube bundle from dust, rain, snow and exposure. Meanwhile, it has advantages of equal air distribution, low noise, long service time and less heat exchange circulation.

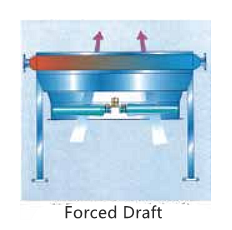

Forced Draft Type

Forced draft type air cooled heat exchanger is easy for maintenance because the fin tube bundle is mounted on the top of the fan and air duct; the fan motor is mounted below of the equipment . In addition, the fan motor has longer service life because of the lower work temperature.

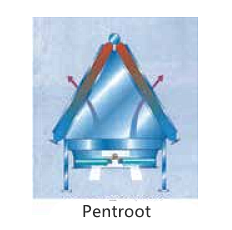

Pent-roof Type

The fin-tube bundles are mounted on the top of the framework at a slant angle of 60°, this covers a smaller area and suitable for gas condensing. The resistance of inside tube and heat transfer coefficient of pent-roof air cooled heat exchanger are better than the horizontal type.

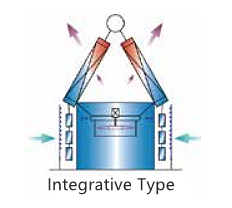

Integrative Type

Fin-tube bundle (Part I) is mounted on the top of framework at a slant angle of 60°, it covers a smaller area. Fin-tube bundles (Part II) are placed at the both sides of the fan air inlet, and the water spraying system is installed at the windward side of the tube bundles. The water spraying system will greatly enhance the thermal discharge performance of the equipment under the condition of extremely high temperature.